In today’s competitive elevator industry, customers need safe, stable, and high-quality products. I know that strong production is very important for making great elevators. At LJ Elevator, we use 10nos production lines to build excellent quality. This shows our professionalism and our promise to serve our customers well.

A Complete Production Process: From Design to After-Sales Service

Our production system covers every key step of making an elevator. We have a main machine production base, a sheet metal base, an escalator assembly base, a parts production base, a main control system base, a logistics center, an elevator research center, a training center, a product testing center, and an after-sales service center. These 10nos lines work together as a complete chain. This helps us control every step from raw materials to finished products and even after-sales service.

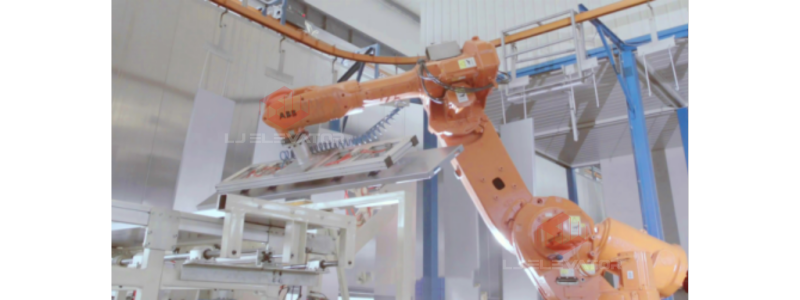

For example, at our main machine production base, we make the main elevator structure using advanced robots and automated machines. At our sheet metal base, we focus on making the elevator car and door parts with precise cutting and bending.

Each production base has its own quality monitoring system. We follow strict ISO standards and check every step carefully. This process reduces mistakes and gives our customers strong quality assurance.

Detailed Production Bases: Every Step Ensures Quality

Escalator Assembly Base and Parts Production Base

Our escalator assembly base puts together the whole escalator and moving walk. Here, automated assembly lines and skilled technicians make sure each part fits perfectly. At the parts production base, we carefully process each key part. We control the materials and techniques strictly so that every part meets top international standards.

During our production, every part is well designed and is checked carefully before assembly. This makes sure our elevators work well and last a long time. Because of this, our products have clear advantages in safety, stability, and longevity.

Main Control System Base and Elevator Research Center

The safety and smart features of an elevator depend on its control system. At our main control system base, top automated equipment and a skilled team ensure every control system reacts fast and runs smoothly. At our elevator research center, we work on new technology and product innovation. We meet today’s needs and also lead future trends. We believe that constant innovation keeps us ahead in the competition.

These two bases work closely together. They make sure our elevators not only have strong hardware but also smart control. This gives our customers a safer and more intelligent experience.

Full-Chain Management: From Logistics to After-Sales Service

Logistics Center

Our logistics center is a key part of our production system. Whether shipping within China or overseas, we use an efficient system to deliver every elevator quickly and safely. With real-time tracking, our customers can see where their product is. This builds trust and makes our service clear.

Training and Testing Centers

Great products come from skilled work and careful testing. Our training center teaches our workers and partners the latest techniques and methods. At the testing center, we use top equipment to check every product. We measure the look, size, and performance of each elevator. This dual system gives each elevator a strong quality guarantee.

After-Sales Service Center

Delivery does not end our service. Our after-sales service center is here to offer long-term support and maintenance. Whether it is regular checks, fixing issues, or upgrading systems, we respond quickly. We believe that good after-sales service builds our reputation and long-term cooperation with customers.

Our Advantages: Fast, Accurate, and Reliable

Working together, our 10nos production lines allow us to run our production smoothly and focus on excellence. Here are some key benefits our bases bring:

- Fast Production and Scale

Our concentrated production layout helps us produce at a large scale. This lowers costs and increases overall capacity. Our efficient logistics and automated machines help us respond quickly, saving time and resources. - Accurate Quality Control

Each base has its own quality check system. Strict processes and standard operations ensure every product meets international quality standards. This improves safety and reduces after-sales repairs. - Technology and Talent

Our research center and training center help us bring in new technology and train skilled workers. Continuous innovation and talent growth let us meet market needs and push the elevator industry forward. - Full Service and Trust

From making the main machine to after-sales service, we have a complete production and service system. Customers enjoy customized, high-quality products and worry-free service. We believe that a strong service system builds trust and long-term partnerships.

A Real Example: How Our Bases Help Projects Succeed

In many projects, our production strength has earned high praise from customers. For example, in one high-end office building project, the customer needed an elevator that met strict safety rules and matched the building design. With our main machine and sheet metal bases, we made an elevator car with perfect size and beautiful appearance. Then, our main control system base provided a high-performance control system that made the elevator smart. The project was delivered on time, and the customer praised our quality and service. This helped build a long-term partnership.

Similar successful cases are common in our history. Every time we produce with high standards and careful quality checks, we keep our promise to our customers. This increases trust in our brand and helps us expand in international markets.

Looking to the Future: Constant Improvement and Excellence

At LJ Elevator, we always watch the latest trends and technology. In the future, we plan to add more smart manufacturing and digital management to our current bases. This will further improve our production speed and quality. We also want to increase international exchanges and bring more new ideas to our company. This way, we can offer our global customers even better and smarter elevator products and services.

Our goal is not only to meet current needs but also to offer forward-thinking solutions for future markets. By improving our processes and upgrading our testing techniques, we aim to lead the elevator industry to a higher standard. We want every elevator to be a perfect mix of safety, intelligence, and beauty.

Conclusion

At LJ Elevator, we believe that strong production is the cornerstone of our success. Our 10nos production lines cover everything from design to after-sales service, ensuring high quality at every step. This rigorous process builds trust and supports long-term partnerships with our customers. Let us work together to create a safer, smarter, and higher quality future.

If you have any questions about our production systems or products, please feel free to contact us. We are always ready to discuss customized solutions with you.