For more details on the LJ Freight Elevator, please contact us. Our team is ready to assist.

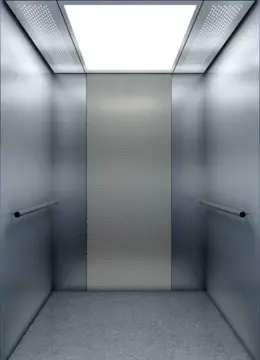

The LJ Freight Elevator is built to handle heavy-duty transportation needs with unmatched reliability and durability. As a leading freight elevator manufacturer, we specialize in designs that cater to warehouses, factories, and logistics centers. Our freight elevators feature reinforced cabins, high-capacity hoisting systems, and customizable load capacities to suit various industrial demands.

Safety is never compromised. Advanced technologies like overload protection, anti-slip flooring, and a secure locking mechanism ensure smooth and safe operations. These elevators are engineered for efficient goods movement and long-lasting performance.

LJ Freight Elevator is built for heavy-duty applications, offering robust performance and customizable load capacities. Its safety features guarantee reliable and secure goods transportation.

LJ Elevator is a trusted provider of heavy-duty Freight Elevators, designed to meet the rigorous demands of industrial and commercial environments. These elevators feature robust cabins, high-capacity hoisting systems, and customizable load capacities, making them ideal for warehouses, factories, and logistics centers. Engineered for durability and efficiency, they optimize space usage within facilities while ensuring smooth and reliable transportation of goods. With advanced design options, LJ Freight Elevators can accommodate diverse structural requirements, enhancing operational flexibility.

LJ Freight Elevators are designed with reliability and safety in mind. Featuring overload protection, a secure locking mechanism, and reinforced cabin structures, they are built to meet the tough demands of industrial operations. Our IoT-enabled systems allow for remote tracking, diagnostics, and maintenance, ensuring seamless and safe goods transportation with minimal downtime.

Our custom service for freight elevators is tailored to your industrial and logistical needs. We offer a detailed consultation to determine load capacity, cabin size, and other requirements, providing a range of customization options to suit your operations. Every custom freight elevator is rigorously tested for durability and safety. We deliver clear and precise quotations, adhere to agreed timelines, and provide thorough after-sales support. Our mission is to provide a high-performance elevator that meets your heavy-duty needs while exceeding your expectations.

We adhere to a unified service standard and maintenance process across our global network. This ensures that all our elevators are maintained at the highest standards, guaranteeing their safety and performance.

We handle each client's data on a one-to-one basis, enabling us to formulate exclusive maintenance plans that cater to your specific needs. This personalized service is designed to meet your elevator's unique requirements.

Our team is trained to respond promptly to any emergencies. We understand that time is of the essence in such scenarios, and we strive to resolve any issues as quickly and efficiently as possible to minimize any disruption to your operations.

Our full-time service team is available 24/7 to respond promptly to your demands. We prioritize quick and efficient solutions to meet your needs promptly.

We offer comprehensive training for your staff to ensure they understand the operation and safety features of our elevators. Additionally, our support team is always ready to assist with any queries or issues you may have.

Our advanced smart systems allow us to remotely monitor elevator operations. This gives us real-time access to safety information, ensuring a secure environment for users.

Is your freight elevator struggling to handle your current operations? LJ Elevator offers Freight Elevator Renovation services to ensure your equipment meets modern industrial demands. From upgrading load capacities to enhancing safety systems, our skilled team can revamp your freight elevator to deliver reliable, efficient, and durable performance for years to come.

No solution to the problem you are struggling with? Welcome to consult us, we have the most professional team.

The primary difference between a freight elevator and a normal elevator (also called a passenger elevator) lies in their design, purpose, and capacity. Here's a breakdown:

1. Purpose

2. Capacity

3. Interior Design

4. Door Mechanism

5. Speed

6. Controls

7. Building Code Requirements

8. Access

In short, freight elevators prioritize durability and capacity, while normal elevators focus on passenger comfort and convenience.

Yes, it is possible to install a freight elevator in a building that does not have a machine room. This is actually a common consideration in modern construction and renovation projects, especially for buildings where space is limited or where a machine room is not feasible. In such cases, machine-room-less (MRL) freight elevators are a viable solution

The typical speed of a freight elevator depends on its design, purpose, and building height. Freight elevators are generally slower than passenger elevators because they prioritize heavy lifting and durability over speed. Here are common ranges:

Standard Freight Elevators:

Speed: 50–200 feet per minute (fpm)(about 0.25–1 meter per second).

High-Capacity Freight Elevators (in taller buildings):

Speed: 200–500 fpm(1–2.5 meters per second).

The maximum load capacity of a freight elevator varies based on its design, application, and classification. Here are typical ranges:

1. Standard Freight Elevators

2. Heavy-Duty Freight Elevators

3. Custom or Specialized Freight Elevators

Classification Types (Based on Load Handling)

The elevator's size, platform reinforcement, and building infrastructure determine its load capacity. Specialized installations can exceed these ranges for unique applications.

At LJ Elevator, We turn complex Into Simple! Follow the following three steps to start today!

Please provide us with as specific your needs as possible, and share your thoughts.

We will determine the best solution based on the requirements you provide and provide a specific quote within 24 hours.

Upon your approval and a 30% deposit, we will begin production and take care of shipping.

If you want to simplify the Inquiry process, DOWNLOAD our Inquiry format, fill in as many details as possible, and send it to us as an attachment. We will give you our suggestions.

We are a leading supplier of elevators and escalators, known for our quality, innovation, and exceptional customer service.

WhatsApp us