In modern homes, elevators are no longer just a convenience but a crucial part of daily life. As home elevators become more popular, safety concerns have become a top priority for users. One of the key issues is how to effectively detect obstacles during operation and prevent accidents.

The Caplift Series by LJ Elevator introduces an innovative Mechanical Safety Touch Plate Protection System, an advanced design that significantly enhances elevator safety. Compared to traditional electronic sensors, Caplift floating mechanical touch plate provides instant obstacle detection and an immediate stop function, eliminating potential hazards and making safety truly within reach.

1. What is the mechanical safety touch plate protection system?

The Mechanical Safety Touch Plate Protection System is an active safety device installed in key areas of the elevator’s operating path. It performs three essential functions:

- Real-time detection of obstacles in the elevator’s movement path, such as children, pets, or objects;

- Immediate triggering of the stop mechanism upon detecting an obstacle, preventing entrapment or crushing incidents;

- Unlike optical sensors, this system relies on physical contact feedback, making it immune to environmental interference and ensuring long-term stable operation.

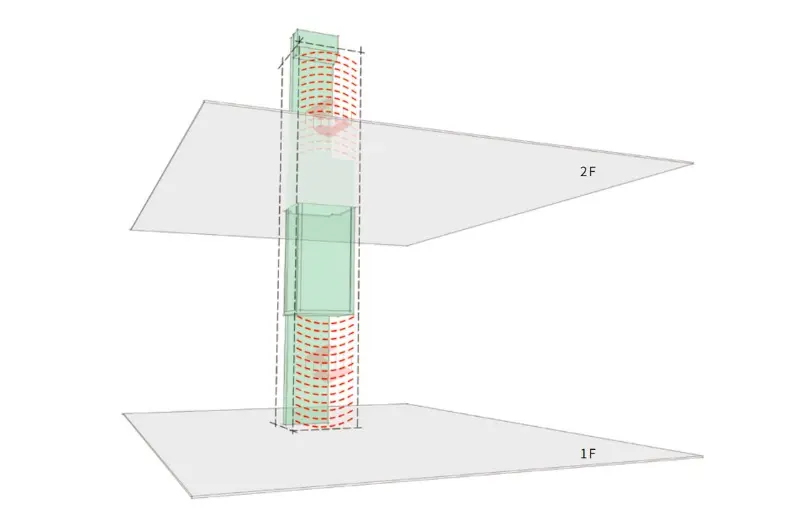

How it works

Caplift floating mechanical touch plate, exclusive to LJ Elevator, operates through physical contact. If an object is detected in the elevator’s path, the touch plate automatically sends a signal to the control system, which immediately stops the elevator, preventing any potential accidents.

The biggest advantage of this system is its zero-delay response. Unlike electronic sensors, which may have detection lag due to environmental interference, the mechanical touch plate reacts instantly, ensuring the highest level of safety in all conditions.

2. Unique advantages

1. Floating design for enhanced sensitivity

Caplift floating structure is more sensitive compared to traditional fixed safety devices. It accurately detects obstacles near the elevator shaft, including:

- A child accidentally entering the elevator area,

- A pet wandering too close,

- Small objects falling into the movement path.

The floating design ensures that even the slightest contact triggers an immediate stop.

2. Fully mechanical protection – stable and reliable

- Uses mechanical contact detection instead of electronic sensors, eliminating the risk of signal interference or system malfunctions.

- Not affected by environmental conditions such as humidity, dust, or electromagnetic interference, ensuring consistent performance.

- Operates without requiring electrical power, meaning it remains functional even during electrical failures, offering an added layer of security.

3. Proactive safety mechanism to prevent risks

Unlike passive optical sensors, Caplift Mechanical Safety Touch Plate is an active safety system, offering superior protection:

- Optical sensors rely on infrared detection, which may malfunction under strong sunlight or other lighting conditions. The mechanical touch plate, however, functions reliably regardless of external light sources.

- The touch plate can detect even small objects (such as a baby’s finger or a pet’s tail), which standard optical sensors might miss.

- When triggered, the system not only stops the elevator but also engages the BLIS blind-spot monitoring system for secondary confirmation, further enhancing safety.

4. Lower maintenance costs & extended lifespan

- Unlike electronic sensors that degrade over time, mechanical safety devices are more durable, reducing maintenance requirements.

- Fewer system failures, ensuring long-term reliability and lower operating costs.

- Longer lifespan than traditional optical sensors, making it a cost-effective safety solution.

3. Caplift vs. traditional optical sensors

| Comparison | Caplift Mechanical Safety Touch Plate | Traditional Optical Sensors |

| Trigger Mechanism | Physical contact – stops instantly upon touch | Infrared or electronic detection |

| Reaction Speed | Zero-delay response | May experience minor delays |

| Stability | Immune to electromagnetic interference | Prone to failure under harsh conditions |

| Maintenance Cost | Low, highly durable, and maintenance-free | Sensors degrade over time, requiring frequent replacements |

| Suitability | Ideal for homes and commercial settings | May be unreliable in bright or dusty environments |

From the comparison above, it is evident that the Caplift Mechanical Safety Touch Plate provides superior performance in terms of reaction speed, stability, and maintenance costs, making it a better choice for home elevator safety.

4.How to protect your home?

Caplift Mechanical Safety Touch Plate is particularly beneficial for:

- Families with Elderly or Children – Prevents accidents when children unknowingly approach the elevator doors.

- Pet Owners – Ensures that pets’ tails or paws do not get caught in the elevator.

- High-End Residences and Villas – Offers enhanced safety and reduces maintenance costs for homes with frequent elevator use.

- Environments with Variable Lighting – Unlike optical sensors, the mechanical touch plate is not affected by lighting conditions, ensuring stable performance in bright or dim areas.

5. Conclusion

As home elevators become increasingly common, safety must remain a top priority. The Caplift Mechanical Safety Touch Plate, an industry-leading technology, provides a more stable, faster, and cost-effective safety solution.

When choosing a home elevator, safety should be the number one factor. Caplift Mechanical Safety Touch Plate Protection System ensures that every user enjoys a secure, smooth, and worry-free experience.

- Zero-delay response – stops instantly upon contact

- Mechanical detection – stable and unaffected by environmental conditions

- Works in all lighting conditions – avoids sensor failures in bright sunlight

- Lower maintenance costs and extended product lifespan

When it comes to safety, we make no compromises. Choosing Caplift means choosing a better-protected home, a safer ride, and complete peace of mind.