At LJ Elevator, we always look for ways to improve our manufacturing process. One of our greatest strengths is our smart factory. With advanced equipment and technology, our smart factory makes our elevators safer, more efficient, and custom-made for your needs.

Embracing intelligent production

Our smart factory is the heart of our production process. Here, we use modern machines to automate many tasks. This means our work is fast and precise. In our factory, you will find advanced systems that help us make every part of an elevator with great care and consistency.

In our previous article, we talked about our 10 production bases that ensure top quality from design to after-sales service. You can read more about that here: Our Production Strength.

Advanced equipment in our smart factory

Let me introduce you to some of the advanced equipment in our smart factory:

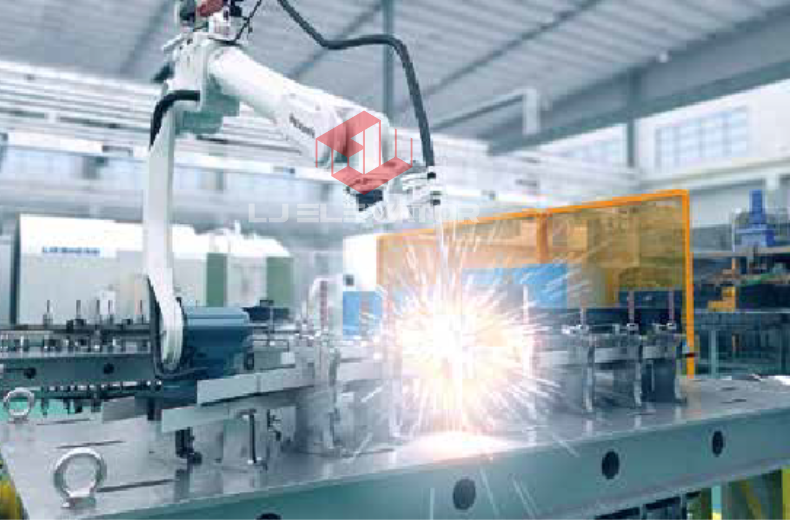

Automatic welding robots

We use automatic welding robots to join metal parts with precision. These robots work quickly and make strong welds. With them, we reduce human error and ensure that every weld meets our high safety standards.

Dutch WEMO production line

Our Dutch WEMO production line is another highlight. This line uses top-quality technology from the Netherlands. It helps us process materials with high accuracy and speed. This means that the parts we make are both reliable and durable.

German wagner powder coating line

For a perfect finish, we use a German Wagner powder coating line. Powder coating is a process that gives our parts a smooth, even surface. This line ensures that the coating is applied uniformly. As a result, our products have a strong, attractive, and long-lasting finish.

Finnish fully-automatic sheet metal flexible production line

Our Finnish fully-automatic sheet metal flexible production line is key to making precise metal parts. This line is flexible and can handle many different shapes and sizes. With it, we produce elevator car bodies and door panels that fit perfectly together. This contributes to both the safety and beauty of our elevators.

SMT surface mount technology production line

We also use an SMT (Surface Mount Technology) production line for electronics. This line places and solders electronic components onto circuit boards with great precision. It is very important for our control systems, ensuring they work reliably and quickly.

The investment behind our smart factory

Our commitment to quality is backed by significant investment. In our smart factory, we have put in over 1,100 pieces of production equipment and more than 6,000 sets of production fixtures. The total value of this investment exceeds 200 million yuan. This strong investment helps us stay ahead with modern technology and ensures that our production is both efficient and high quality.

Every piece of equipment in our factory plays a vital role in our manufacturing process. They work together to create a smooth production line that minimizes waste, reduces production time, and improves the overall quality of our elevators.

Benefits of a smart factory

Our smart factory brings many benefits:

- Efficiency and speed:

Automation speeds up our production process. With machines like welding robots and automatic production lines, we can produce more elevators in less time. - High precision:

Advanced equipment ensures that every part is made exactly as designed. This precision is key to safety and quality. - Consistent quality:

With strict quality checks and advanced technology, every product is built to the same high standard. This consistency builds trust with our customers. - Flexibility and customization:

Our smart factory can easily adapt to different designs and requirements. Whether you need a unique finish or specific features, our technology lets us customize products to meet your needs. - Reduced costs:

Efficient production helps us lower waste and reduce costs. This means we can offer high-quality products at competitive prices.

Our commitment to innovation

At LJ Elevator, innovation is not just a buzzword—it is the core of our business. We continue to invest in new technology and modern equipment. Our smart factory is always evolving with the latest advances in automation and digital control. This commitment helps us improve our products and meet the growing demands of the global market.

We believe that our smart factory sets us apart. By combining traditional craftsmanship with advanced technology, we create elevators that are not only reliable and safe but also elegant and tailored to your building’s design.

Real-world impact

Let me share a real-world example. In one recent project, a client needed elevators with exceptional quality and a unique design to match a modern building. With our smart factory, we were able to produce custom parts that met their exact requirements. The automatic welding robots ensured strong joints, while the powder coating line provided a flawless finish. The client was very satisfied with the final product, and our efficient production helped deliver the project on time.

This is just one example of how our smart factory makes a difference. Every day, our advanced production lines contribute to the success of projects all over the world.

Looking to the future

We are excited about the future of our smart factory. As technology advances, we will continue to upgrade our equipment and processes. Our goal is to keep pushing the boundaries of quality and efficiency. We want to offer our customers the best possible elevator solutions, backed by modern, intelligent production.

Our smart factory is not only a symbol of our production strength—it is a promise of continuous improvement and innovation. By integrating more digital systems and smart machines, we aim to set new standards in the elevator industry.

Conclusion

Our smart factory is a key part of LJ Elevator success. With advanced equipment like automatic welding robots, Dutch WEMO production lines, German Wagner powder coating lines, Finnish flexible sheet metal lines, and SMT production lines, we create elevators that are safe, efficient, and custom-made. Our investment of over 1,100 machines and 6,000 fixtures, worth more than 200 million yuan, speaks for itself. Learn more about our production bases in our previous article here. Together, we are building a smarter and safer future.

If you have any questions about our smart factory or our products, please feel free to contact us. We are always ready to help you find the perfect elevator solution.